Not known Incorrect Statements About Best Dust Extractors

Wiki Article

Excitement About Best Dust Extractors

Table of ContentsExamine This Report about Best Dust ExtractorsGetting The Best Dust Extractors To WorkWhat Does Best Dust Extractors Do?Best Dust Extractors Can Be Fun For EveryoneSome Known Factual Statements About Best Dust Extractors Some Known Questions About Best Dust Extractors.

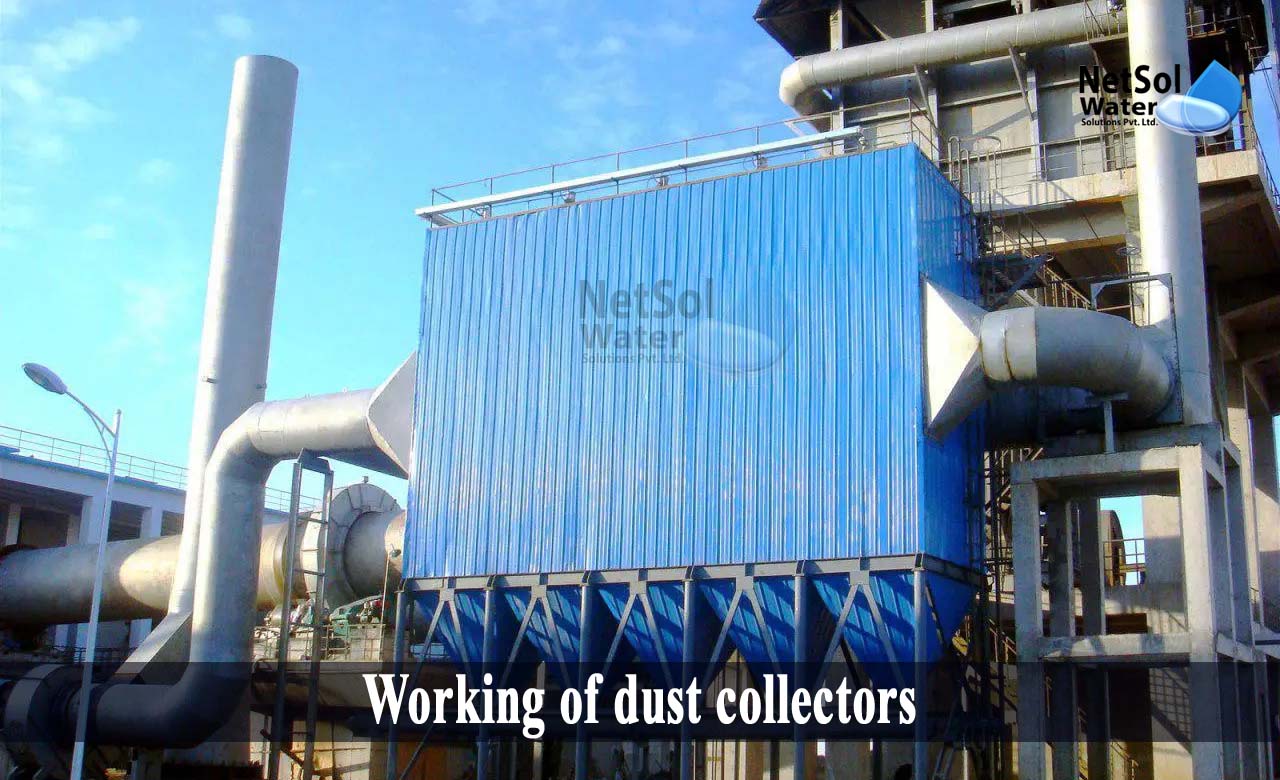

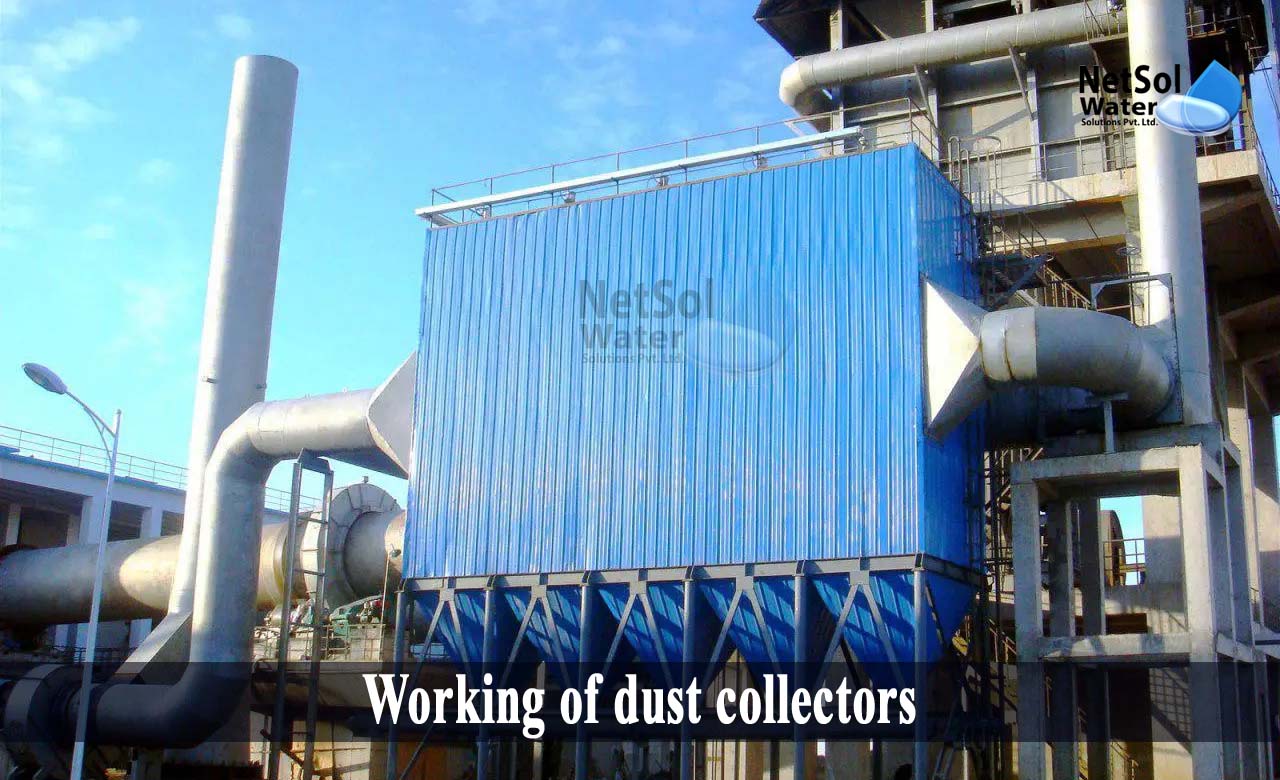

Dust control systems for mining procedures have to hold up against heavy use but be flexible enough to adjust to a vast range of conditions. The nature of mining dirt needs extremely strong as well as reputable devices given that mining dirt can be rough and also rough as well as extremely great. The various sorts of mining determine the kind of dirt collection system.

The dirt fragments from fiberglass have a tendency to stick together despite if the procedure is grinding, reducing, or a few other type of shaping. To meet the standards of OSHA and also NFPA, fiberglass dirt collection systems must have fire and also explosion protection parts. The air high quality for fiberglass dust control systems is very closely monitored as a result of the health and wellness threats.

Finishing, or thermal spray, applies warmed product to steels to layer their surfaces. Dirt collection systems for this sort of operation should be especially developed to fit the kind of covering being used. The objective of the system is to control and also reduce overspray and also dirt. The normal thermal spray dirt control system utilizes ducts to relocate air to the collection device.

Though it would appear likely to raise air movement and also motion, this kind of solution may mishandle and waste energy. The style of the booth relies on the force of the air entering the cell or cubicle. For the majority of systems, it is necessary to have a slight vacuum in the booth to prevent possible positive pressure (Best Dust Extractors).

The Ultimate Guide To Best Dust Extractors

Another technique is just positioning the make-up air link on the top of the cubicle. No matter the layout, it is essential for the cleaning of the air to have cross air flow. A lot like a cleanroom, air movement in a thermal spray booth can be either horizontal or downward, though the downward design is best for dirt collection systems.When manufacturers choose a dirt control system, they are recommended by manufacturers regarding the type of system that would best fit their demands given that purchasing and setting up a dust control system is a major financial investment. Particulate matter comes in a vast selection of types, from silicon dust to timber chips as well as sawdust.

Carbon Fine carbon dust can be found in various manufacturing procedures and also is gotten rid of utilizing polyester filters. Best Dust Extractors. Molybdenum Molybdenum dust is created during the mining procedure and is gotten rid of making use of a baghouse system. Spice Dirt Spice dirt is created by the production of any kind of spice, from cinnamon to sesame seeds.

Metal Chips Grinding operations generate metal chips that need to be removed for the safety of employees. Baghouses as well as scrubbers are used for air movement filtering. Sawdust This is the most common product removed by dirt collection systems. Cartridge or baghouse approaches can be used, with baghouse being the most effective.

Not known Details About Best Dust Extractors

Textile filter bags in a cartridge system are the most reliable technique for gathering dust. Cement Concrete dust is created during the activity and transport of the product. Dust collection systems are covered to see this include the dirt and tidy the air. Clay Clay dirt is created in the manufacturing of blocks.

Plastic Dust High-Density Polyethylene (HDPE) dirt is produced in the production of plastic panels when they are shaped as well as based on a side trimmer, mill, or miter saw. Paper Dirt Among the extra common types of dirt is paper dirt, the side effect of the production of various kinds of paper.

With the intro of dust collection systems, employees are much safer and also a lot more protected. Pulse jet systems are utilized to keep the filters of the dust collection system particulate-free.

A baghouse system is the recommended system. Rice Dust Rice dirt has very great and minute particles that gather during the production of rice-based items. A dust collection system is required for the protection and also safety of workers. Silica Silica is among the most usual substances in the world. It is a central part of numerous manufacturing procedures, such as the manufacturing of glass, ceramic tile, concrete, as well as asphalt.

Best Dust Extractors Can Be Fun For Everyone

Aesthetic Powders The manufacturing and manufacture of cosmetic items create a large amount of dust that conveniently moves to all locations of the manufacturing facility and also makes the air hazardous. To control the problem, producers set up dust collection systems such as baghouse as well as cartridge kinds. Shot Blasting Dirt collection systems for shot blasting and sandblasting click here for more info are required to accumulate the blowing up product, particles, as well as dirt.

The material from the procedure can harm devices. The dirt collection system helps by getting rid of blast product. Rock Dust Rock dust collection systems are utilized at quarries as well as mining procedures. They are heavy-duty equipment designed to operate in rough and also unsafe problems. Their main function is to control ambient dust that is a part of the mining procedure such that it does not spread out from the area of the operation.

In the best problems, gathered dust can become unsafe, dangerous, and also dynamite. Any kind of build-up of dirt, in the existence of the best ignition resource, can create an explosion. In specific situations, dust can self-ignite without requiring an igniting representative, such as when fixed accumulates as the particles scrub together.

An initial understanding of the conditions that develop eruptive dirt offers firms with the understanding to avoid such conditions and be positive in their reaction. Considering that explosions can potentially damage employees, the Office for Safety and also Health Management (OSHA) has created a set of standards to assist business in ensuring employee security.

Getting My Best Dust Extractors To Work

Other actions that can aid in making a dust-filled setting safe are: Explosion Vents Explosion vents can be set up on a dust enthusiast system to supply alternate methods for fires or broadening gasses to get away. Surge Latches Surge latches operate under the very same principle as surge vents.Preventative Maintenance Strategy Of the different techniques to take care of possibly explosive problems, correct care of the building and maintaining areas tidy are the simplest and also most logical approaches for preventing eruptive and combustible conditions. Such strategies are typically created in coordination with security employees Get More Info and authorities that have jurisdiction.

They trap exhaust as well as lower the temperature of heated bits prior to they go into a dust-collecting gadget. They transport triggers as well as embers away from the dirt collection system, where the triggers are cooled down to protect against explosions and also fire.

Additionally, there are needs concerning the removal of combustible dust fragments. The primary focus of OSHA requirements is a terms of the precautions being taken by a business to safeguard the health and wellness of its employees. No matter of the lack of dirt collection requirements, OSHA does choose that producers have a dust collection system to control dirt accumulation.

The Greatest Guide To Best Dust Extractors

Each market has a various variety of toxins as well as dangerous particles to be gotten rid of. With the expanding problem for the atmosphere, dirt collection systems have actually become important to several industrial as well as manufacturing operations.Report this wiki page